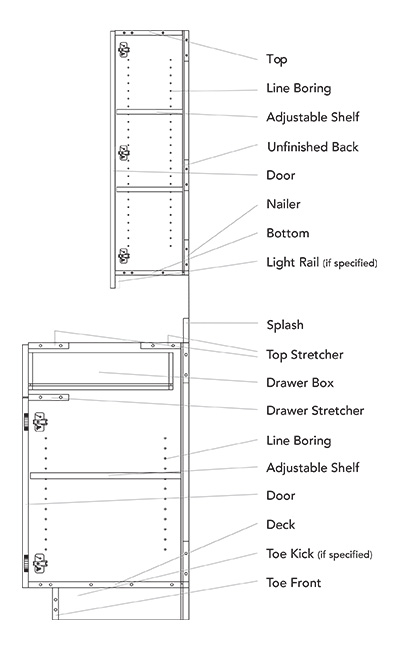

Cabinet Construction

- All parts are 3/4″ thick except back. The customer specifies materials used.

- Dowel Screws (confirmat) are used primarily for assembly.

- Finished ends can be dowel constructed, or a 3/4″ applied finished end can be fabricated from the cabinet’s exterior material. Applied door panels are also available. Corona Millworks will provide inserted hardwood dowels in all horizontal cabinet components for doweled cabinet assembly.

- Backs are 1/4″ thick and dadoed on the sides and bottom of cabinet. Stop dadoes are used on wall-hung cabinet sides.

- Drawer stretchers are placed relative to the size and location of the drawer front.

- Nailers are placed behind the back and are cut from fall-off material (color may vary).

- Construction methods may vary for customers’ specific requests and option fees will apply.

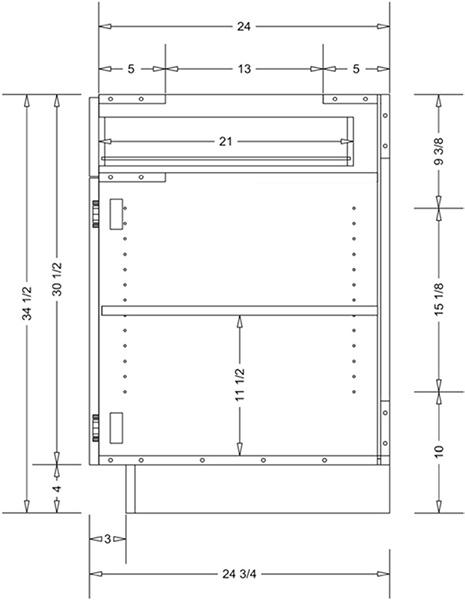

CNC Machining Hardware Hole Layout Methods

- All hardware holes are accurately machined. Holes are placed specifically for each hinge plate, drawer slide, and adjustable shelves.

- Holes required for hinge baseplates are placed relative to the top and bottom of the door. Hinge cups can be bored 3” from the top and bottom edge of the door.

- Drawer hardware holes are placed for the specified hardware and relative to location of the drawer.

- Adjustable shelf holes are placed between the base plates only if adjustable shelves are specified in the cabinet.

- Specify exactly which hardware applications are to be used when placing order. Only hardware called out on the order form will fit on the final machined part.

Cabinetry Detail Illustrated